“La METALGROS” has specialized in the construction and installation on site of steel metal structures in general, in the construction of systems for the transport and handling of flat glass, such as roller conveyors and conveyor belts, as well as in the construction and installation of driveway gates and in the installation of REI fire prevention doors. Recently, we have also built and installed hydraulic gates and augers for hydroelectric power stations. We also carry out maintenance either on the equipments manufactured by us and on automated industrial plants.

Our workshop is equipped with load handling devices, such as overhead cranes with 5000 kgs loading capacity, lift-trucks having 2500-4000 Kgs loading capacity, Merlo crane P38.14, 500 kgs Jib crane. We also have CNC machines for cutting and bending sheet steel, semi-automatic machines for cutting, punching and drilling beams, MAG continuous wire welding machines, etc.

Among our customers we include construction companies, multinational industries operating both in the rubber field and in the glass chemical field. Over the years we have also been involved in many projects all over Europe, both for the supply of steel structures and their installation on site. France, Germany, Switzerland, Belgium are just a few countries to name.

Our major Customers:

CERTIFICATIONS

We are a certified Company as follows:

- ISO 9001 quality certification /RINA certification body

- ISO 18000 safety certification /RINA certification body

- UNI EN ISO 1090 certificate for structural metal constructions /RINA certification body

- Certification according to EN13241-1:2003+A1:2011 Gates /Certification body: Tecno Piemonte

- Welders licensed according to UNI EN 287-1 /RINA body

- Welding procedures certified according to UNI EN ISO 15614-1 /RINA body

STAFF & TRAINING

The whole staff responsible for the construction of our structures and involved in the installation is composed of people employed directly by our organization, who have followed specific training courses both in terms of safety and tasks to be performed.

Amongst the training courses held for our staff, we mention:

- Safety course according to the “Italian Country and Piedmont Region Agreement” 16 hours (all employees)

- Forklift truck and telescopic boom crane operation (11 employees)

- Use of Elevating Platforms (7 employees)

- First aid course (9 employees)

- Low risk fire course (6 employees)

- Average fire risk course (4 employees)

In addition, courses are periodically held internally for the use of the various machines available at our workshop, as well as for the use of the PPE devices supplied to our employees, among these are the courses for the use of safety slings and retractable fall arrest devices.

OUR HISTORY

“LA METALGROS” was born in 1958, first under the name of "GROSSO FRATELLI" and whose members were three brothers (Lorenzo, Antonio and Giuseppe GROSSO). The company specializes in the construction of steel structures (tanks and fences) and performs maintenance on agricultural machines.

In 1964 the company moves the production to a new location in Margarita (Cuneo), Via Umberto I, n°04, given the further increase in staff (about 12 units), and expands the production range by also inserting pipes for the heating sector.

MICHELIN

A further step forward occurs in 1968, when the company begins a close collaboration with MICHELIN in Ronchi. For the developing "GROSSO FRATELLI" company this collaboration involves a further widening of the production range with the inclusion of steel structural constructions (such as warehouses) and gives a new impetus to the company's maintenance activity.

“LA METALGROS”, our Company

The last significant step forward in chronological order took place in 1977 when the company "GROSSO FRATELLI" was transformed into today's "LA METALGROS" with the inclusion of the respective sons and daughters of the Grossos’ brothers in the company, thus ensuring a generational change for the company.

SAINT-GOBAIN SEKURIT

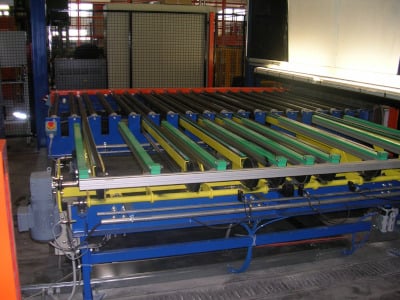

Since the mid-90s, “La METALGROS Snc” has been collaborating with the Saint-Gobain Sekurit group, initially as labor suppliers for the maintenance and transfer of lines for the production of automotive glass in Savigliano, and later on not only for the construction and assembly of safety partitioning fences in connection to parts of existing lines and glass transport lines, such as belt, roller and band conveyors, but also for specific equipment for the manufacture of windshields for cars, as drying and extrusion ovens, including the so-called white or controlled temperature rooms, robotized unloading / loading bays and so on. This experience led us to work also for further branches and companies like Sicurglass and Euroveder in Cervasca. Over the years, this collaboration has led our company to deepen its knowledge in the field of flat glass transport and therefore to create specific equipment in that working sector.

BOTTERO

The experience gained over the years on the construction of the aforementioned lines has led us to create for the company Bottero S.p.a. wheeled and belt conveyors for flat glass for their automated lines mounted all over the world, such as Spain, Belgium, Brazil, United States etc.

SICURGLASS

Again, for the Saint-Gobain group and more specifically for Sicurglass, in the late 90s and early 2000s we collaborated for the assembly and commissioning of ovens and lines dismantled from other group factories scattered throughout Europe.

Our company took care of both the disassembly on site and the reassembly with the various adaptations in their factory in Cervasca, near Cuneo. In addition, in the following years, we have carried out all the necessary works connected to the safety of these lines and built the soundproof cabins to reduce noise. In the mid-2000s, we collaborated with other companies to move the entire Sicurglass plant from Cervasca to Savigliano.

BUILDING & CONSTRUCTION WORKS

In the building & construction field, we have been collaborating with several companies in this sector for many years, including EDITEL Spa of Nucetto, for which we still manufacture and install light and heavy steel structural products in general, such as canopies, mezzanines, pedestrian doors, windows, swing or sliding gates. Among the various works carried out for EDITEL over the years, there has been the renovation of the former Olivetti offices in Ivrea, the renovation of shopping centers such as Panorama in Settimo Torinese, the various refurbishment works at the Molinette hospital in Turin, as well as at the various Telecom and Enel offices scattered throughout the north-west of Italy. Besides, the construction and assembly of the running mezzanine for the rotary press installed at the ILTE in Moncalieri, the construction works at the Michelin offices in Turin, Cuneo and Alessandria, with the assembly of REI 120 fire doors etc., can be mentioned within the extent of this collaboration.

STEEL STRUCTURAL WORKS

For Michelin, Italian headquarters in Cuneo, in addition to making steel structural items, such as structures for supporting lifting equipment or sheds as well as equipments for the production of tires, we take care of the maintenance of the buildings, especially the part concerning the replacement and/or repair of the gates and of the fire doors from the Ferr Edil company.

ARCHITECTURE, INTERIOR DESIGN & FURNITURE

During the past decades, we have also been involved in the construction of the facade and interior furnishings of the Roagna Vivai, a plant nursery in Cuneo. Under the guidance of the architects commissioned by the client, we have created both the load-bearing structures, and the various access stairs, the various display equipment inside the greenhouses and their relevant signs. The various equipment were made both in iron and stainless steel.

Still in the context of architectural structures and furnishings, we have created the furnishings and accessories for Polleri, a photographer’s shop in the center of Savona: our work was mentioned in the magazine dedicated to architecture (PAI Award 2012).